Introduction

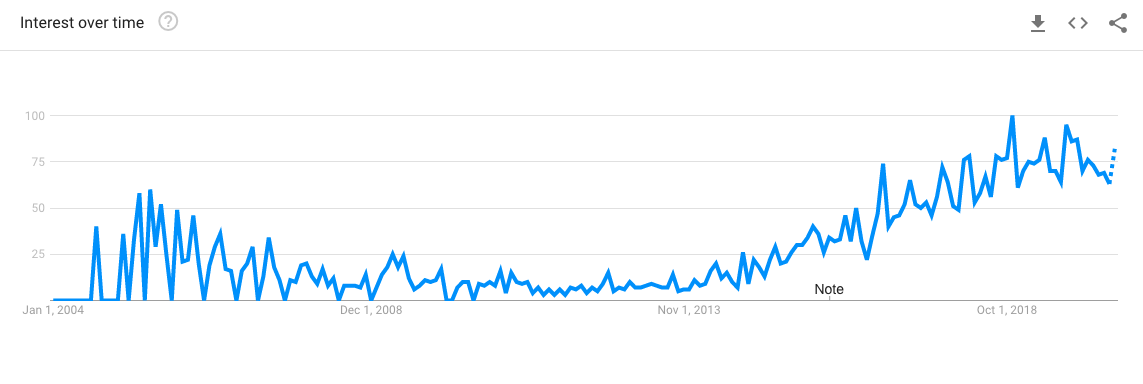

While interest in the smart factory has been growing since around 2013, achievements in this area seem uneven. Successes seem to rub shoulders with failures, giving a diffuse impression of hesitation and slowness by far. But on closer inspection, the picture changes. A number of signals indicate that the smart factory is already a reality.

Components of the Smart Factory

To make a plant, or more generally an intelligent industrial asset, is to add :

- Sensors, associated with existing industrial assets, possibly in the form of drones;

- New types of industrial assets, including 3D printing;

- Connecting industrial assets to the digital cloud;

- AI techniques for developing applications, including predictive maintenance and cybersecurity.

The smart factory is the term towards which Industry 4.0 is moving.

One sector ahead of the smart factory: oil & gas

Oil and gas is a sector that has been undergoing a digital transformation in recent years, as Nathalie Brunelle pointed out at DYSTOPIA 2019, particularly with regard to the Total/Tata Refinery 4.0 project. The determining factor in this transformation, which is still in progress, lies in the massive reduction of maintenance costs for infrastructures massively equipped with sensors. In this sector, the killer app of the intelligent plant is therefore all the rage.

No general killer app yet

On the other hand, we have noted in the past that there is no general killer app at this time that would alone determine the adoption of the smart factory in all sectors. But perhaps this opinion should be qualified. Does the brake lie in the absence of a killer app, or rather in the interest of developing smart factory type applications without going through an external platform? Knowing that the two factors can combine: reluctance to share data, and insufficient performance gain to overcome this reluctance.

Conjecture: Tesla will be the first automaker to have a smart factory… in Shanghai

It has long been apparent that Tesla’s goal is to revolutionize automotive manufacturing, even if it is sometimes forgotten. Tesla’s business is not only to produce cars, batteries, and solar panels but also to produce the factories of the future from which the energy transition will emerge. At least that is the credo of Elon Musk, who believes that the energy transition will require building a hundred gigafactories.

The road to the Smart Factory, however, is not easy for Tesla. The challenge of automation had to be put on hold for a while in order to meet short-term production targets. These challenges peaked in the summer of 2018. However, the goal has always been for Elon Musk to build factories that are “alien dreadnoughts”. And production figures from the new Gigafactory in Shanghai suggest that Musk is fast approaching that goal. Giga Shanghai already produces more than 3000 Model 3s per week. Expansions to produce the Model Y are currently under construction. The target by 2021 is to produce 250k vehicles per year, which would put Tesla on par with the major established manufacturers. And this with a growing share of components made in China. In the same perspective, it will be exciting to follow the fate of the gigafactory in Berlin-Brandenburg.

Conclusion: the intelligent factory, an unevenly distributed reality

The smart factory is not tomorrow, it’s already a reality now. But an unevenly distributed reality. Next question: What about you? What’s your status? We are asking this question because Presans’ business is increasingly about creating synergies between different sectors or industrial players. For this, we need to know more about you, and where you are in your adoption of new technologies. This will enable us to help you to set up a Synergy Factory on this topic.