Introduction

The fundamental question that interests us at open-organization.com is basically always the same: Are the technologies that make up the global industrial innovation agenda the best technologies? This is a difficult question, the answer to which presupposes knowing how technology is put on the agenda, and why technology is optimal. But it is a question that cannot be ignored by industrial innovation players.

One of the technological themes that are high on the global industrial innovation agenda at the beginning of summer 2020 is 3D printing. The term encompasses a whole set of additive manufacturing processes that have in common that they are controlled according to a digitized plan in the form of a computer file. In this article, we will examine why 3D printing is currently a major topic for industrial innovation. First, we will recall some stages in the recent history of this technology; then we will indicate some bases concerning its nature and ramifications; finally, we will examine, in a third stage, the current signals allowing us to anticipate its future developments.

What happened with 3D printing from 2013, and why?

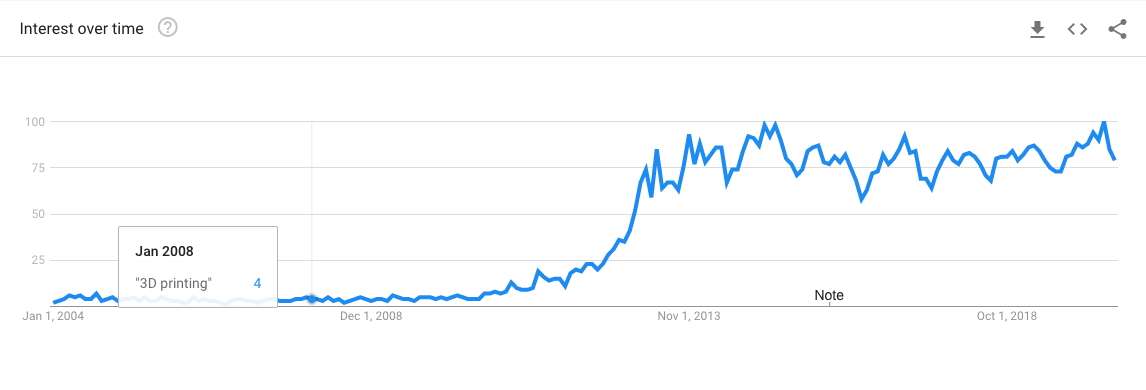

As suggested by the Google Trends graph above, 3D printing began to occupy a higher place on the global technology agenda during the 2010s, with strong growth in public interest in this topic in 2013. This buzz is largely the result of a major speech by Barack Obama.

Why this speech? For one thing, because even back then, the relocation of industrial activities was a major political issue in the USA, following the financial crisis of 2008. This crisis has indeed ravaged some industrial regions, plunging entire segments of the population into distress (the rest is known). 3D printing is one of the technologies that give hope of a return to activity.

On the other hand, the development of the market for 3D printers for individuals was blocked until the end of the 2000s by a patent held by Stratasys (US patent 5121329). Stratasys is indeed a pioneer in 3D printing only active on the professional market, whose business model is not transposable to the personal printer market. But in 2009, Stratasys’ patent fell into the public domain, and the way was paved.

One factor contributing to the enthusiasm of the early 2010s around 3D printing is its potential to decentralize productive activities, even suggesting to some the contours of an “America 3.0”. 3D printing is also making headlines in the USA because it can be used to print firearms. Overall, a small elite of pioneering users is forming around 3D printers… including our Fellow Philippe Perrier, who is also speaking in the WAR #1 webinar). But at the BtoC level, things are generally calming down fairly quickly. The action will take place elsewhere, in professional and industrial uses.

3D printing is rapidly becoming an integral part of the industry 4.0 agenda, which itself falls within two major narrative frameworks: digital transformation, accelerating or not towards a Singularity (utopian or dystopian), and ecological transition, managing to reduce or not reduce environmental risks. Since 2014, the world of 3D printing has been meeting in Frankfurt at the FormNext trade fair, which is growing steadily in size. 3D printing is making its way through a wide variety of sectors with its prowess and announcements:

- Tissue engineering makes it possible to produce artificial skin that can be used for testing, particularly in the cosmetics industry;

- Prosthetics, implants, bio-printed organs… the medical applications of 3D printing are revolutionizing many health professions;

- In the field of food, 3D printing is one of the ways of texturing meat without meat; a technique to be distinguished from in vitro meat culture… unless the latter has to be categorized as bio-printing, or even self-assembly (but in any case we are in the very long term);

- Aerospace: production of parts with complex shapes; at the project stage: 3D printing of lunar bases ;

- Automotive: rapid prototyping; tool production; mold production; complex-shaped parts; spare parts; at project stage: refillable tires;

- Nuclear: 3D printing can bring performance gains to the nuclear industry, particularly in the certification of parts; at project stage: 3D printing of nuclear power plants;

- Industrial Resilience: 3D printing has recently played a major role in the industrial players’ response to the COVID-19 health crisis, see our recent webinars We Are Resilient: 1 & 3.

This list is far from exhaustive, but it gives an idea of the impressive variety of sectors impacted and suggests that the 3D printing market could tomorrow expand beyond its current technological niches. However, to become a general-purpose technology that generates new innovations, 3D printing still needs to be the subject of large-scale profitable investments. This is one of the challenges of the current period: to associate good business models with this technology.

3D printing, explained by Presans

Several industry groups have asked Presans to study how 3D printing can impact their business sectors, leading open-organization.com to devote a short introductory article on 3D printing. Our Chief Fellow, Hervé Arribart, also covered the subject in more depth in one of our webinars.

Presans 3D Printing Webinar Guide

Introduction

01:25: Distinction between 3D printing and additive manufacturing ;

03:14: Additive manufacturing is an enabling technology (very similar to general-purpose technology);

04:12: Ancestral vs. modern additive manufacturing;

05:30: objectives of the presentation: issues in additive manufacturing, factors limiting adoption.

Introduction to 3D Printing

05:57: Example of the process: powder bed melting; voxel ;

08:42: Printable materials and their applications;

12:57: 3D printing and materials science;

14:56: the 6 advantages of 3D printing; the economic frontier between additive and conventional manufacturing;

18:30: who uses additive manufacturing and why?

21:43: the engine made by Renault Trucks is a feat ;

22:16: the complex shapes that can be printed and cannot be produced by conventional manufacturing;

23:35: the production of personalized objects;

24:42: the spare parts;

25:22: distribution of uses in 2018; projection into the future according to industrial sectors;

27:08: the brakes and the challenges;

29:40: conclusions.

The main ideas

The dominant industrial use is prototyping. Almost all design offices, fab labs and engineering schools have 3D printers.

Manufacturing by 3D printing of metals is interesting in the case of complex shapes and/or small series. For polymer objects, however, conventional plastic injection molding is generally preferable.

Evolution since 2018

Hervé informs us that 3D printing of ceramics seems to have made progress since the date of the webinar. Beyond ceramics, the printing of metals is currently changing very quickly, as we will see.

2020 and beyond: Combining cooperation and competition

The end of 2010 saw acquisitions of 3D printing specialists by major industrial groups such as Michelin (AddUp), Xerox (Vader Systems), or BASF (Sculpteo). This development signals that in several industrial sectors, 3D printing is becoming an increasingly crucial component of business models.

In the case of Michelin, 3D printing is used on the one hand to make tire molds. This application corresponds perfectly to the case where the object to be made has a complex shape. On the other hand, 3D printing is intended to be used in tire recharging. The targeted business model corresponds very clearly to the user-centric & functional dimension of the open organization key. Combined in particular with regrooving, tire recharging by 3D printing makes it possible to perfect a model based not on the sale of tires, but on the sale of the function performed by the tire: the kilometer of a tire.

In the case of Xerox, the business model discussion is a classic for all open innovation enthusiasts and Henry Chesbrough readers. But instead of losing most of the benefit of its inventions because it did not have a suitable business model in the 1970s (to the benefit of Steve Jobs and Bill Gates), the Xerox of the 2020s includes a 3D printing offering because this technology shows every sign of being able to fit into its existing business model. A model in which the sale of printers represents only 20% of the company’s revenue, with the bulk of the business including contractual services, maintenance, and consumables. A very remarkable point about this new offer is that it includes metal printing and that it is positioned on mass production. Another point to be examined more closely is the use of liquid metal instead of metal powders. This advance, if confirmed, would be revolutionary. Liquid metal technology could allow Xerox to implement a platform business model… or even become a 3D printing branch, after having long held that position in 2D printing.

For BASF, this means continuing its strategy of positioning itself as a partner of choice in the market for materials used in 3D printing. Logical for an industrial chemistry group.

The discussion about business models for printing often leads to intellectual property issues, based on an analogy with the digital transformation that swept away the old music record industry. Our impression is that this dimension is, however, less important in the context of the industrial uses of 3D printing. As long as manufacturers manage to maintain their ability to lock access to their data, the intellectual property problems associated with 3D printing may ultimately remain quite limited.

Ultimately, we believe that the near future of 3D printing will be determined by the ability of ecosystems to judiciously combine industrial cooperation logic with winning competitive strategies based on sound economic models. Our webinar on mobilization around the Ocov mask provides a remarkable case of articulation between these two dimensions.

Conclusion

Why is 3D printing currently a major subject for industrial innovation? Because, by dint of its prowess, this technology is likely to become a new general-purpose (or enabling) technology in the near future, provided that suitable economic models are found.

The key to the future of 3D printing lies in its ability to enable both new uses and new business models. The role of industrial players is to explore this enabling capacity collectively. In this spirit, Presans organizes Synergy Factories that bring together a plurality of companies around subjects combining technology, use cases, and economic models. After all, why not ensure that the systemic choice of an optimal technology takes into account these decisive factors from the outset, which too often are treated as adjustment variables, or as aspects of industrial policy added after the fact in an agenda over-determined by considerations of a completely different nature?