What are Ultra-High Performance Concretes (UHPCs)?

UHPCs are a new class of cement-based materials emerging in several structural applications. With respect to normal concrete, UHPCs are endowed with unprecedented compressive strength (150 MPa), tensile ductility (0.1%), and toughness (30 kJ/m2), which makes UHPC structures impermeable and durable under serviceability limit states. At the material level, UHPC material properties can be further optimized by means of heat curing and the optimal choice of the fiber reinforcement. At the structural level, the design of UHPC structures can be enhanced by means of steel reinforcement, pre-stressing actions, and the combination with steel or other materials in hybrid structures.

What are the advantages of UHPCs?

UHPCs effectively enhance construction sustainability by reducing the lifetime costs of a structure and by improving its environmental impact.

UHPCs applications are expanding

- Bridges

- Footbridges

- Buildings

- Containers

- Pre-cast panels

- Concrete foundations in harsh environments

- Marine civil structures

- Marine constructions

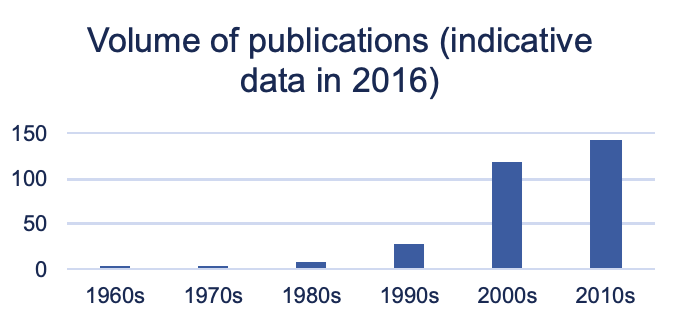

UHPCs are still evolving

Source : Presans

Terminology has evolved in the past few decades and is now solidifying under the influence of new norms and national design guidelines. We may currently distinguish:

- UHPFRCs: low brittleness through Fiber Reinforcing (FR), either metallic (for the highest compressive strength) or non-metallic.

- Non FR UHPCs, which tend to have higher brittleness.

Should UHPCs be on your technological agenda?

Presans can help industrial innovators find out more about new applications for UHPCs.